Similar

A study of haymaking crews and labor costs (1918) (14761612661)

Summary

Identifier: studyofhaymaking578mccl (find matches)

Title: A study of haymaking crews and labor costs

Year: 1918 (1910s)

Authors: McClure, H. B. (Harry B.), 1879-

Subjects: Hay Agricultural laborers

Publisher: Washington, D.C. : U.S. Dept. of Agriculture

Contributing Library: U.S. Department of Agriculture, National Agricultural Library

Digitizing Sponsor: U.S. Department of Agriculture, National Agricultural Library

Text Appearing Before Image:

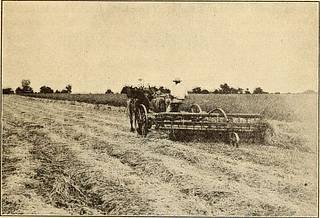

0 or more acres. For such areas the laborcost with the loader usually is less than that of loading by hand,and more work will be done by a crew using a loader than by thesame crew pitching by hand. The loader is used to best advantageif a side delivery rake is used, for the reason that after but oneround has been made with the rake the loader can start. (See %. 5.) When the yield is heavy the rake can be dispensedwith and thehay taken directly from the swath. The loader adds considerablyto the cost of the hay equipment, and repairs are quite an item if itis not properly handled. Many farmers say that hired help do not like to use the loader,because it makes the work of building the load a strenuous job.Slings can be used to advantage with the loader. HAYMAKING CREWS AND LABOR COSTS.Method 10. 13 This method was found on a farm where help was scarce and thecrew short. The first load is put on by one man, the other rakingwith side-delivery rake. When load is on, the second load has been

Text Appearing After Image:

Fig. 5.—The side-delivery rake in operation. It puts the hay in loose windrows which allow a free circu-lation of the air. If used, however, when the hay is nearly cured, there is liable to be a large leaf loss,especially with legume hay. raked. Both men go to barn and unload. The second, and everyalternate load thereafter, both men load. They change places everyother load. The team on wagon needs no driver when loading.This method calls for very hard work. The amount of hay made isabove the average for a two-man crew. Work Chart 10.— Timothy and clover loaded ivith loader and unloaded ivith horse fork (Ohio). (This method is adapted to 60 acres.) Operation Men Teams Time required 6 7 8 9 10 11 12 1 2 J if. <? 6 7 Stowing.- Raking AAarBAarB(IB) aab(b) 1 1 1 1 1 1 1 1 I 1 1 1 1 1 mmmmmmmmmm rrrrrrrrrTrr hhhhhhhhhhhh uuuuuuuuuuuu 1 1 1 ! 1 1 1 1 1 1 1 I 1 1 Hauling Unloading Two men and four horses put up 9 tons (6 acres) per day. Yield, 1.50 tons per acre. Man-hours 1.83,team-ho

Tags

Date

Source

Copyright info