Similar

Transactions (1871) (14749914856)

Summary

Identifier: transactionsmining23amer (find matches)

Title: Transactions

Year: 1871 (1870s)

Authors: American Institute of Mining, Metallurgical, and Petroleum Engineers

Subjects: Mineral industries

Publisher: New York (etc.)

Contributing Library: Gerstein - University of Toronto

Digitizing Sponsor: University of Toronto

Text Appearing Before Image:

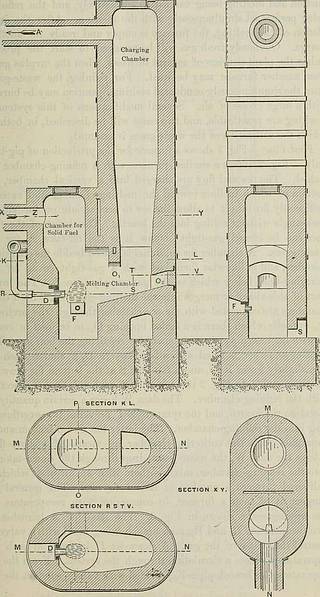

ined (desiliconized) or partlyrefined (decarburized), that is to say, if the foreign elements are tobe removed, the metal, on its way to the collecting-chamber afterthe removal of the slag, is brought into intimate contact with hot,heat-producing and intensely oxidizing gases. Thus the foreignelements are wholly or partly eliminated. By maintaining a suffi-ciently high temperature in the collecting-chamber to preserve thematerial in a molten state during the progress of the decarburization,the product, depending on the extent to which the refining is car-ried, will be refined pig-iron, ingot-sfeel or ingot-iron. With alower temperature in the collecting-chamber than the melting-pointof the intended product, weld-metal will be produced. Working of the Process,Intermittent Worhing. There are two ways of carrying on the process, either by inter-mittent or continuous working. By the intermittent plan the pro- NEW PROCESS FOR PRODUCTION OF PIG-IRON, ETC. 7 SECTION M N. Fig. f. SECTION O P.

Text Appearing After Image:

GAS-FuRNACe FOR THE INTERMITTENT PRODUCTION OF PiG-IrON. 8 NEW PROCESS FOR PRODUCTION OF PIG-IROX, ETC. cess is conducted upon a single furnace-charge; the preparation, re-duction and melting being carried on successively, and the refiningbeing performed simultaneously with the melting. After the com-pletion of the melting, the furnace is empty and ready for anothercharge. Obviously fresh gas will be required to start the processunless the plant consists of several furnaces, when the surplus gasesfrom another furnace may be used. For refining, the waste-gasesfrom the simultaneously conducted melting-operation may be burnedwith a large excess of air. Several modifications of this system ofworking are practicable, and two cases will be described, in both ofwhich the utilization of the waste-gases is assumed. Fiist Case.—Fig. 1 shows a furnace for the production of pig-irononly. Fig. 2 shows a similar furnace with a refining-chamber at-tached. The ore and flux are charged into a vertictransactionsmining23amer

Tags

Date

Source

Copyright info