Similar

Textile raw materials and their conversion into yarns - (the study of the raw materials and the technology of the spinning process) a text-book for textile, trade and higher technical schools, as also (14782393514)

Summary

Identifier: textilerawmateri00zips (find matches)

Title: Textile raw materials and their conversion into yarns : (the study of the raw materials and the technology of the spinning process) a text-book for textile, trade and higher technical schools, as also for self-instruction ; based upon the ordinary syllabus and curriculum of the Imperial and Royal Austrian weaving schools

Year: 1901 (1900s)

Authors: Zipser, Julius Salter, Charles

Subjects: Textile fibers Spinning

Publisher: London : Scott, Greenwood

Contributing Library: Claire T. Carney Library, University of Massachusetts Dartmouth

Digitizing Sponsor: Claire T. Carney Library, University of Massachusetts Dartmouth

Text Appearing Before Image:

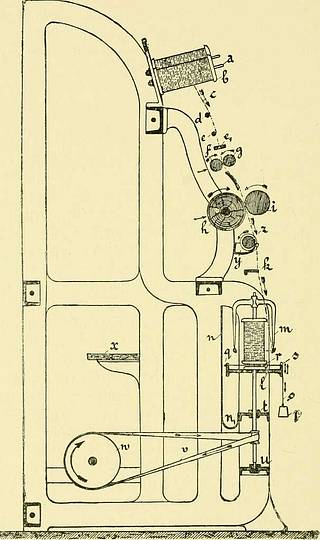

d, finally, to the flyer spindle, ni (of which there are56 to 88 on each side of the frame), and the bobbins, wherethey receive the necessary twist and are wound. The arrange-ment of the spindles is the same as in the cotton fly frame,except that, instead of the bobbins being caused to drag byleather and felt washers, this result is produced by a brakecord, 0, and a weight, p. This cord, which is fastened on therear edge of the bobbin traverse at q, is led round the whorlon the lower flange, r, of the pulley, and placed in one of thegrooves on the front edge, s, of the traverse. The larger thesurface of contact between the cord and the whorl, the greaterthe retardation of the bobbin. The brake tension of the cordsis adjusted by sliding the front edge, s, of the traverse side-ways, by means of special driving gear, at each alternation ofthe traverse, in order to equalise the drag of the whole set of 256 TEXTILE RAW MATERIALS. bobbins. As the bobbins increase in diameter, more drag must

Text Appearing After Image:

Fig. 148.—Flax Dry Spinning Frame (vertical section). be imparted in order to keep the thread tension uniform. TEXTILE RAW MATERIALS. 257 The spindle is mounted in a collar bearing on the rail, t,and in a step bearing on the footstep rail, «, and is driven by aleather belt or cotton band, v, from the tin roller, ic, at a speedof 2,000 to 2,500 revolutions per minute. A foot-board, .y,above the tin roller, enables the minder to conveniently reachany part of the machine for setting and cleaning. 2. The Semi-wd Spinning Frame. On account of the liability of iron to corrosion and leatherto putrefy under the influence of the water used, these materialsmust be replaced in the rollers of semi-wet frames for mediumyarns by brass in the fluted rollers, and beech or gutta-perchafor the pressure rollers. The moistening is effected :—• (a) By allowing cold water to trickle down incessantlyover the pressure rollers. (h) By allowing the lower part of the fluted rollers to dipinto a trough of

Tags

Date

Source

Copyright info